Upgrade Your Equipment with Dependable Bobcat Aftermarket Parts

Upgrade Your Equipment with Dependable Bobcat Aftermarket Parts

Blog Article

Unlocking Prospective: Aftermarket Parts as a Cost-Effective Option for Machinery and Heavy Devices

In the ever-evolving landscape of machinery and heavy equipment maintenance, the utilization of aftermarket components has actually emerged as an engaging alternative worth checking out. While the idea might increase brows amongst reactionaries, the advantages that aftermarket components use in terms of price savings, quality, and efficiency are not to be taken too lightly.

Cost Financial Savings and Worth Proposal

The expense financial savings and worth proposition of making use of aftermarket components for machinery and heavy devices are significant factors that contribute to functional performance and economic viability in different markets. By choosing for aftermarket parts over original tools supplier (OEM) parts, services can recognize considerable cost financial savings without endangering on quality or performance. Aftermarket components are typically much more competitively valued than their OEM counterparts, allowing companies to lower upkeep and repair expenditures while still ensuring the correct performance of their equipment and tools.

Additionally, the worth suggestion of aftermarket components expands past expense savings. These parts are extensively offered and provide a wider selection compared to OEM parts, offering companies with greater adaptability and ease in sourcing the elements they require. Furthermore, aftermarket components are known for their high quality and reliability, conference or also exceeding market standards in most cases. This dependability translates into enhanced functional effectiveness and lowered downtime, eventually improving total efficiency and profitability for organizations that choose to take advantage of aftermarket remedies for their machinery and hefty devices requirements.

Top Quality and Compatibility Guarantee

Stressing the extremely important value of top quality control and compatibility verification is important when considering the usage of aftermarket components for machinery and heavy devices. Making sure that aftermarket parts meet or surpass market criteria for high quality is essential to keeping the ideal performance and durability of the machinery. Quality control actions, such as extensive screening procedures and certifications, offer confidence to devices proprietors that the aftermarket components will certainly operate dependably and successfully.

Boosted Accessibility and Alternatives

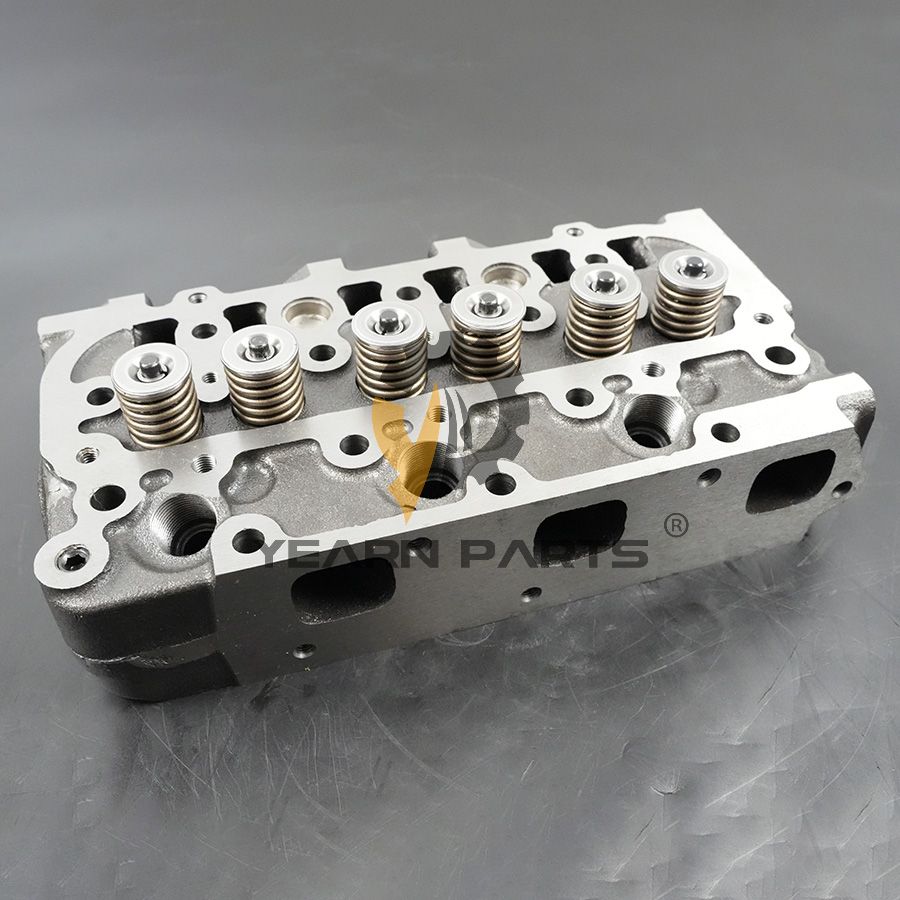

With an increasing market and growing need, aftermarket parts for machinery and heavy tools are currently providing raised schedule and a wider variety of choices to provide to the diverse requirements of devices proprietors. This rise in accessibility is driven by the aftermarket parts industry's commitment to satisfying the certain demands of numerous equipment brand names and designs. Devices proprietors can now access a broad variety of aftermarket components, ranging from engine components to hydraulic parts, electrical systems, undercarriage components, and extra.

Furthermore, aftermarket components manufacturers are constantly increasing their product to include components for a wider variety of machinery and hefty devices, guaranteeing that proprietors can locate appropriate substitutes despite the devices type or version they possess. This increased schedule and range of aftermarket parts encourage equipment owners to make economical choices without endangering on high quality or performance. Therefore, they can effectively keep, repair, and update their equipment with self-confidence, knowing that aftermarket components use a trusted choice to OEM components.

Performance and Longevity Advantages

Enhancing machinery and hefty tools with aftermarket components brings notable performance and toughness benefits to devices proprietors. Aftermarket components are typically created with innovations in innovation and products, offering boosted efficiency here are the findings compared to original devices manufacturer (OEM) components. Updated parts can result in enhanced power, performance, and overall machine abilities, bring about boosted productivity and functional efficiency.

Additionally, aftermarket components are regularly crafted to be a lot more lasting and resilient than their OEM counterparts. This raised sturdiness can convert to reduced downtime for repair and maintenance, ultimately conserving tools owners beneficial time and cash. By buying aftermarket parts recognized for their toughness, machinery and heavy tools can stand up to extreme operating problems and heavy work with higher resilience.

In significance, the efficiency and toughness advantages of aftermarket components contribute substantially to optimizing the capability and long life of equipment and heavy equipment. Equipment proprietors stand to acquire an affordable edge by leveraging aftermarket remedies to boost the general efficiency and resilience of their properties.

Sustainability and Environmental Effect

The use of click here for more info aftermarket parts not only enhances the efficiency and toughness of equipment and hefty devices but likewise plays a pivotal role in attending to sustainability issues and lowering ecological effect. By choosing aftermarket components, sectors add to the reduction of waste generation because these parts are frequently sourced from recycled materials or with remanufacturing processes. This method aligns with the principles of a circular economic situation, where resources are utilized efficiently, and waste is lessened.

Additionally, aftermarket parts can expand the lifespan of equipment and devices, minimizing the regularity of replacements and consequently lowering the general carbon footprint connected with manufacturing brand-new equipment. Additionally, the production of aftermarket components commonly entails much less energy intake and less emissions compared to making initial devices producer (OEM) components - Bobcat Aftermarket Parts. This change to aftermarket parts sustains eco-friendly techniques by promoting reusability and source conservation within the industrial sector. Inevitably, the combination of aftermarket parts into machinery maintenance and repairs is a sustainable strategy that benefits both services and the setting.

Verdict

To conclude, aftermarket components provide an economical service for machinery and heavy equipment by providing price savings, top quality assurance, raised schedule, efficiency advantages, and sustainability advantages. These components not just provide a sensible option to original tools maker components but additionally add to the overall efficiency and longevity of machinery and devices. Accepting aftermarket parts can result in substantial price financial savings and enhanced performance, making them a useful option for services looking to optimize their sources.

By deciding for aftermarket components over original tools producer (OEM) parts, services can realize substantial cost financial savings without compromising news on top quality or efficiency (Bobcat Aftermarket Parts). Devices proprietors can now access a wide array of aftermarket components, ranging from engine parts to hydraulic parts, electric systems, undercarriage components, and much more

Additionally, aftermarket components suppliers are continuously increasing their product lines to include components for a wider range of machinery and hefty devices, making sure that proprietors can discover ideal replacements regardless of the tools type or version they have. Aftermarket components are commonly developed with improvements in modern technology and products, offering improved efficiency compared to initial devices maker (OEM) parts. Additionally, the manufacturing of aftermarket parts frequently entails less energy consumption and fewer discharges compared to producing initial equipment manufacturer (OEM) parts.

Report this page